GORE® DVI Cables (Digital Only) for Civil Aircraft

Single-link cables from Gore are built purposely for the digital component of airborne DVI systems and fit effortlessly into standard hardness designs. Our cables stream high-speed data and video, support high-resolution aircraft displays, meet stringent requirements, and perform reliably in grueling aircraft conditions.

联系我们

+1 800 626 7708

Germany

+49 9144 6010

+49 9144 6816 (fax)

UK

+44 1382 56 1511

+44 1382 56 1007 (fax)

Italy

+39 045 6209 209

+39 045 6209 165 (fax)

France

+33 1 5695 6565

+33 1 5695 6401 (fax)

Spain

+34 93 480 6900

+34 93 373 7850 (fax)

Sweden

+46 31 7067800

+46 31 864226 (fax)

China (Beijing)

+86 10 5707 4999

+86 10 5707 4900 (fax)

China (Shanghai)

+86 21 5172 8299

+86 21 6247 9199 (fax)

China (Shenzhen)

+86 755 8359 8262

+86 755 8359 1654 (fax)

South Korea

+82 2 393 3411

+82 2 393 1285 (fax)

Japan

+81 3 6746 2582

+81 3 6746 2571 (fax)

Overview

Today's data-intensive aircraft requirements are pushing the need for cables that can stream data and video reliably at higher speeds in airborne digital video interface (DVI) systems. Cables must also meet stringent industry requirements necessary for reliable performance in DVI systems operating in demanding radar environments. But, engineers often face the challenge of designing harnesses with digital components that turn out to be insufficient for harsh aerospace environments.

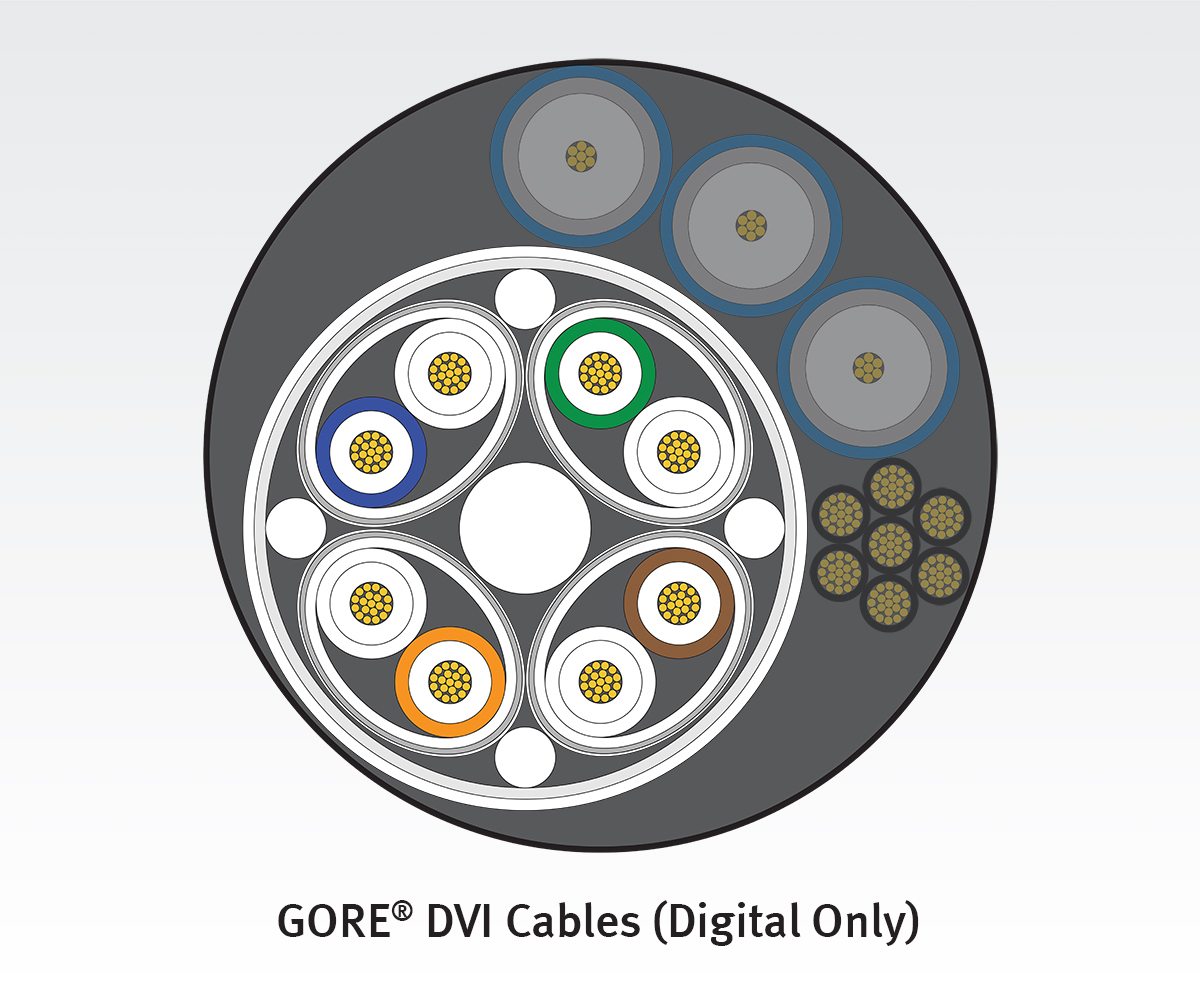

Standard DIV harness cross-section

Optimal Viewing on Displays

GORE DVI Cables are designed specifically for the digital component of airborne DVI systems. Our single-link cables deliver exceptional signal quality supporting the highest video resolution for optimal viewing on aircraft displays. Unlike many substitutes, our cables meet strict requirements for impedance control, insertion loss, skew, and EMI shielding — providing stable performance in demanding radar environments.

Easy Fit into Standard Harness Designs

Our cables make it easier for design engineers to use them in standard DVI harnesses. They're smaller, lighter weight, and more flexible without sacrificing durability compared to alternatives. So you can fit them easily into a harness cross-section with other components, and they won’t get damaged or break.

Applications

GORE DVI Cables (Digital Only) are engineered to perform reliably in a variety of aircraft applications, including:

- cockpit displays

- flight management systems

- in-flight entertainment (IFE)

- weather mapping

If you have any questions or to discuss your specific application needs, please contact a Gore representative.

Benefits

GORE DVI Cables (Digital Only) provide aircraft system architects and engineers with many benefits that improve electrical and mechanical performance such as:

- single-link configuration built specifically for digital component of DVI systems

- exceptional signal quality for high-speed data/video transmission

- support highest resolution on aircraft displays for optimal viewing

- meet strict requirements for impedance control, insertion loss, skew, EMI shielding

- robust protection and stable performance in demanding radar environments

- easily fit into standard DVI harnesses with small, lightweight, flexible designs

- compatible with variety of high-speed aerospace connector systems/backshells

For more information about the benefits of our cables, please contact a Gore representative.

Properties

These values demonstrate the electrical, mechanical and environmental performance of GORE DVI Cables (Digital Only).

| Electrical Property | Value |

|---|---|

| Standard Impedance (Ohms) | 100 ± 10 |

| Typical Operating Voltage (V) | <15 |

| Nominal Velocity of Propagation (%) | 80 |

| Nominal Time Delay ns/m (ns/ft) | 4.07 (1.24) |

| Capacitance pF/m (pF/ft) | 40.0 (12.0) |

| Maximum Skew ps/m (ps/ft) Pair-to-Pair Within Pair |

52.50 (16.0) 13.12 (4.0) |

| Dielectric Withstanding Voltage (Vrms) Conductor-to-Conductor Conductor-to-Shield |

1500 1000 |

| Mechanical / Environmental Property | Value |

|---|---|

| Jacket Material | Engineered Fluoropolymer |

| Jacket Color | White (Laser Markable) |

| Conductor | Sliver-Plated Copper Alloy |

| Conductor Color-Coding | Blue/White, Brown/White, Green/White, Orange/White |

| Dielectric Material | ePTFE/PTFE |

| Temperature Range (°C) | -65 to +200 |

Part Number & Drawing

Download the drawing to view cable characteristics, like diameter, weight, minimum bend radius, and insertion loss.

| Part Number | AWG Size (Stranding) |

|---|---|

| GSC-01-85249-24S | 24 (19/36) |

Qualifications

GORE DVI Cables (Digital Only) have undergone substantial qualification testing to ensure they meet the most current industry standards and our customers’ requirements.

- ABD0031 (AITM 2.0005); BSS7230; FAR Part 25, Appendix F, Part I: Flammability

- ABD0031 (AITM 3.0005); BSS7239: Toxicity

- ABD0031 (AITM 3.0008B); BSS7238; FAR Part 25, Appendix F, Part V: Smoke Density

- ANSI/NEMA WC 27500: Environmental Testing, Jacket and Marking

- SAE AS4373™: Test Methods for Insulated Electric Wire (Contact Gore for available data)

For more information about the qualifications of our cables, please contact a Gore representative.

Resources

Catalog: GORE® High Speed Data Cables for Aerospace & Defense

Brochures, Data Sheets, 7.28 MB

Brochure: GORE® Aerospace Cables and Materials for Civil Aircraft

Brochures, 1.06 MB

View all resources for GORE DVI Cables (Digital Only) for Civil Aircraft

近期新闻

美国戈尔公司今日宣布旗下产品GORE® PHASEFLEX® 微波/射频测试组件荣获2020年军事与航天航空电子创新奖。经航天航空和国防界经验丰富、广受尊敬的评审团严格评比,戈尔组件具有优异的可靠性和耐久性,在电子战(EW)/雷达装置、电子监控/应对策略、雷达预警系统、导弹接近预警系统以及导航/通信系统的精准测试中发挥关键作用,因而被评为创新奖金奖。

2020国际微波展(IMS2020)上5G连接是关键议题,戈尔为5G测试提供一系列可靠的微波/射频测试电缆组件,将会介绍戈尔电缆组件稳定持久一致的性能,如何确保准确和可靠的测试结果。由于新冠病毒疫情形势依然严峻,此次展览首次在线上举办,具体时间与参与方式请查看后文。

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Contact Us

相关产品

Cables & Cable Assemblies

- 民用航空航天以太网电缆

- Shielded Twisted Pair Cables for Civil Aircraft

- CAN Bus Cables for Civil Aircraft

- Quad Cables for Civil Aircraft

- FireWire® Cables for Civil Aircraft

- Fibre Channel Cables for Civil Aircraft

- USB Cables for Civil Aircraft

- HDMI Cables for Civil Aircraft

- 航空航天光纤电缆

- Cable Protection Systems for Civil Aircraft

- Abrasion Resistant Cable Jacket for Civil Aircraft

Follow GORE® DVI Cables (Digital Only) for Civil Aircraft