GORE® Hook-Up Wires for NewSpace

Designed with robust protection, Gore’s wires provide excellent resistance against extreme temperatures, ATOX and harsh chemicals. They’re proven to safely and reliably distribute power with low-frequency signals throughout the mission. We can quickly deliver a qualified, affordable solution to meet mission demands and stay on schedule.

联系我们

+1 800 626 7708

Germany

+49 9144 6010

+49 9144 6816 (fax)

UK

+44 1382 56 1511

+44 1382 56 1007 (fax)

Italy

+39 045 6209 209

+39 045 6209 165 (fax)

France

+33 1 5695 6565

+33 1 5695 6401 (fax)

Spain

+34 93 480 6900

+34 93 373 7850 (fax)

Sweden

+46 31 7067800

+46 31 864226 (fax)

China (Beijing)

+86 10 5707 4999

+86 10 5707 4900 (fax)

China (Shanghai)

+86 21 5172 8299

+86 21 6247 9199 (fax)

China (Shenzhen)

+86 755 8359 8262

+86 755 8359 1654 (fax)

South Korea

+82 2 393 3411

+82 2 393 1285 (fax)

Japan

+81 3 6746 2582

+81 3 6746 2571 (fax)

Overview

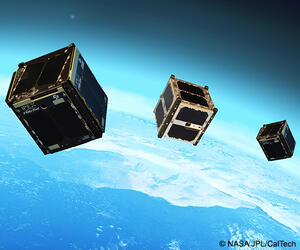

MANUFACTURED QUICKLY AT AN AFFORDABLE PRICE

The hook-up wires used in small satellites and launch vehicles must safely and reliably deliver power to monitor the earth effectively and help us stay connected anytime, anywhere. They must withstand the harshest conditions, like wide-ranging temperatures and atomic oxygen (ATOX). Government and commercial programs also need wires that are reasonably priced and can be delivered on time to meet demanding schedules.

At Gore, we combine decades of expertise in materials technology with proven traditional spaceflight heritage to offer a reliable, affordable wire solution manufactured quickly for the NewSpace industry.

RELIABLE POWER & SIGNALS

GORE Hook-Up Wires are proven to distribute power with low-frequency signals safely and reliably for the entire mission duration. We design our wires with a combination of robust insulation materials that are proven to resist the most demanding spaceflight and orbit conditions while operating at maximum voltage.

For instance, they resist extreme temperatures ranging from -200°C to +200°C, ATOX and radiation exposure while satellites are in orbit. They also withstand severe shock and vibration during vehicle launches. Even harsh chemicals and undesirable fluids won’t degrade the performance of our robust insulation combination. Unlike alternatives available in today’s market, our hook-up wires help meet mission demands without the need for added protection.

Our wires are well-suited for low earth orbit (LEO) and medium earth orbit (MEO) applications -- like optical instruments, electric power supplies and microgravity experiments. When you want an affordable product qualified to NewSpace industry standards and delivered quickly, look no further than proven reliable GORE Hook-Up Wires.

Applications

Well-suited for LEO and MEO missions, GORE Hook-Up Wires distribute reliable and safe power with low-frequency signals in a variety of applications, including:

- DC power distribution

- electric power supplies

- microgravity experiments

- optical instruments

If you have any questions or to discuss your specific application needs, contact a Gore representative today.

Features & Benefits

GORE Hook-Up Wires are engineered with unique features that make them more durable against challenging environmental factors and onboard conditions, including:

- Temperature-, radiation-, abrasion- and ATOX-resistant materials

- chemically inert and low-outgassing materials

- smaller, lighter weight wire diameters

Our wires provide system architects and engineers with many benefits that improve electrical, mechanical and environmental performance such as:

- proven reliable power distribution up to 600 Vrms with low-frequency signals

- excellent resistance against extreme temperatures, ATOX, radiation, chemicals, more

- robust insulation combination help meet mission demands without added protection

- reduced size and weight helps meet challenging mass budgets and tight installation paths

- affordable solution delivered fast to meet demanding program schedules and frequent launch capabilities

- low-risk product qualified to ESA Class 2 and NASA Level 2

- selected complimentary samples with short lead times for prototyping and evaluation

- leverage proven performance with 100% failure-free flight record in hundreds of traditional spaceflight programs

For more information about the features and benefits of our wires, contact a Gore representative today.

Properties

These values demonstrate the electrical, mechanical and environmental performance of GORE Hook-Up Wires for NewSpace applications.

| Electrical Property | Value |

|---|---|

| Voltage Rating Vrms | 600 |

| Outer Insulation Spark Test V AC | 3500 |

| Voltage Test V AC Cable Jacket (ESCC 3901/002 9.7a) Outer Wire Insulation |

1500/2000 2500 |

| Mechanical / Environmental Property | Value |

|---|---|

| Cable Jacket | PFA |

| Cable Jacket Color | Yellow |

| Wire Insulation Material Outer Layer Inner Layer |

PFA Expanded PTFE/Polyimide |

| Wire Insulation Color Outer Layer Inner Layer |

Yellow White/Natural |

| Conductor | Silver-Plated Copper or SPC Alloy, Stranded |

| Temperature Range °C | -200 to +200 |

| Radiation Resistancea MRad | 10+ |

| Vacuum Stability (ASTM 595; ECSS-Q-70-02) Total Mass Loss (TML) % Recovered Mass Loss (RML) % Collected Volatile Condensable Material (CVCM) |

< 0.3 < 0.15 < 0.01 |

| Fluid Resistanceb (ESCC 3901 9.21) | Passed |

aTest conducted using 3 MeV electron irradiation.

bTest results available upon request.

Qualifications

With a thorough understanding of products operating in space, customers’ needs and appropriately scoped NewSpace test procedures, GORE Hook-Up Wires are tested and qualified in adherence to strict standards, including:

- ESA ESCC 3901/018: Polyimide/Fluorothermoplast Insulated Wires and Cables, Low Frequency, 600V, -200 to +200 °C

- ESA ECSS-Q-ST-60-13C, Annex G Class 2: Space Product Assurance — Commercial Electrical, Electronic and Electromechanical (EEE) Components

- NASA EEE-INST-002 Level 2: Instructions for EEE Parts Selection, Screening, Qualification, and Derating

For more information about the qualifications of our wires, contact a Gore representative today.

More Information

LEARN MORE ABOUT GORE HOOK-UP WIRES OR ORDER NOW

We manufacture robust wires to meet demanding LEO and MEO mission requirements and program schedules. To learn more and discuss your exact application, talk to a Gore representative today. Or, contact our U.S. wire and cable distributor for in-stock availability if you’re ready to order now.

We also offer samples of our qualified wires and cables that are complimentary and shipped in the U.S. within 48 hours of your request.

Resources

Brochure: GORE® High Speed Data Cables for NewSpace

Brochures, 1.91 MB

近期新闻

戈尔公司与无数科学家和太空探索爱好者一起,庆祝火星2020任务的“毅力号”火星探测器成功登陆火星。戈尔技术直接在探测任务中发挥了重要作用。

美国戈尔公司今日宣布旗下产品GORE® PHASEFLEX® 微波/射频测试组件荣获2020年军事与航天航空电子创新奖。经航天航空和国防界经验丰富、广受尊敬的评审团严格评比,戈尔组件具有优异的可靠性和耐久性,在电子战(EW)/雷达装置、电子监控/应对策略、雷达预警系统、导弹接近预警系统以及导航/通信系统的精准测试中发挥关键作用,因而被评为创新奖金奖。

FOR INDUSTRIAL USE ONLY

Not for use in food, drug, cosmetic or medical device manufacturing, processing, or packaging operations.

Contact Us

相关产品

Cables & Cable Assemblies

Follow GORE® Hook-Up Wires for NewSpace